Time:2025-11-04 Views:1 source:News

Pogopin fault detection combines electrical testing and mechanical inspection to identify damage, poor contact, and performance degradation, avoiding blind replacement and reducing costs. The process typically includes preliminary visual checks, electrical function tests, and advanced stress testing.

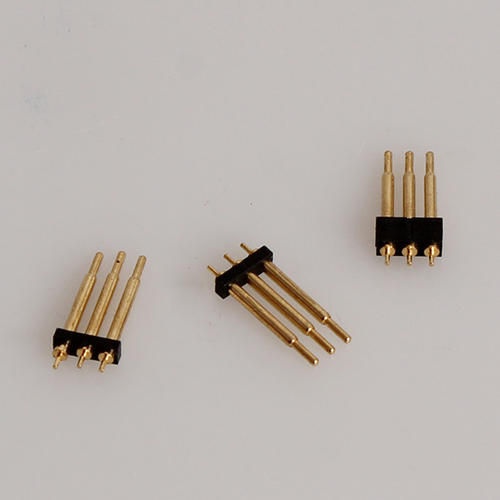

Preliminary inspection starts with visual assessment using a microscope (10–20x magnification). Check for physical defects: bent or deformed needle (common after excessive insertion force), spring fatigue (visible through the barrel), or plating wear (gold plating thickness below 0.5μm reduces conductivity) . Inspect the mounting hole for debris or corrosion, which can cause poor contact. For assembled probes, test mechanical resilience by pressing the head—smooth retraction and full rebound indicate a functional spring; stuck or weak movement signals spring failure .

Electrical testing focuses on contact reliability and continuity. Use a multimeter to measure contact resistance (dynamic resistance should be <30mΩ for standard probes) . For multi-pin arrays, employ a dedicated test fixture with matching Crimp contact point to simulate actual working conditions . Apply standard operating pressure and send test signals to check for open circuits (no signal transmission) or short circuits (cross-talk between adjacent pins). Advanced systems like the STM32-based tester conduct multi-stage pressure tests: first at standard pressure, then 90% and 80% of standard pressure, to identify pins at risk of imminent failure .

Fault classification guides targeted repairs: pins failing the first test are deemed damaged and require replacement; those failing the second test need cleaning or spring adjustment; those passing all tests are marked low-risk . This tiered approach optimizes maintenance efficiency and reduces material waste.

Read recommendations: