Time:2025-12-02 Views:1 source:News

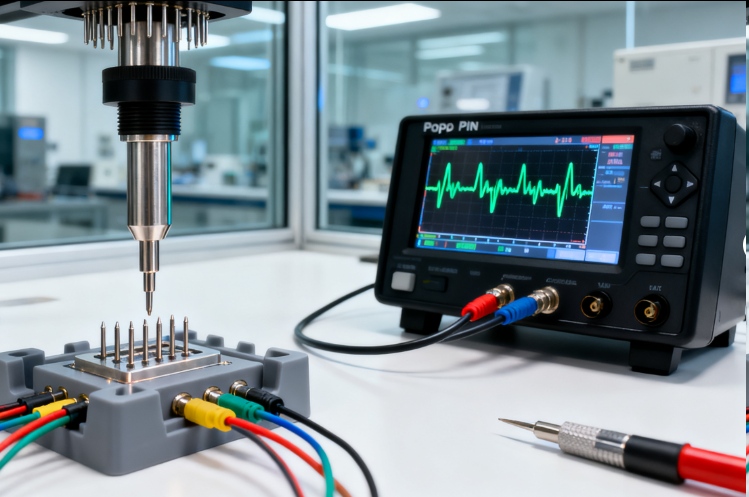

Ensuring reliable electrical performance involves rigorous testing across mechanical, electrical, and environmental domains.

Mechanical Tests:

Contact Retention Force: Measures the maximum axial load before needle retraction. For automotive OBC testing, probes must withstand 5N force without slippage, validated via push-pull gauges.

Spring Force Calibration: Ensures consistent contact pressure (30–80gf). A 50gf force is optimal for TWS earbud charging, balancing insertion ease and electrical stability.

Durability Cycling: Simulates 10,000–100,000 insertions. In MEMS sensor testing, X-Pin probes show <0.01% damage rates after 50,000 cycles due to their rounded tips and分散压力 (pressure dispersion) design.

Electrical Tests:

Low-Level Contact Resistance (LLCR): Uses a 10mV/10mA test to measure oxidation without breaking oxide films. Gold-plated probes maintain <50mΩ resistance, while unplated alternatives degrade to >500mΩ after 1,000 cycles.

Temperature Rise Test: Monitors heat generation under 3A current. BeCu probes in 5G modules exhibit <5°C rise, whereas phosphor bronze alternatives reach 12°C, risking component damage.

High-Frequency Signal Integrity: Tests 30GHz bandwidth in 5G testing. Probes with gold-plated BeCu needles achieve <2dB insertion loss, meeting 3GPP standards.

Environmental Tests:

Salt Spray Resistance: Exposes probes to 5% NaCl for 96 hours. PdNi-plated variants show no corrosion, while gold-plated probes develop pitting in 48 hours.

Thermal Shock: Cycles probes between -40°C and 125°C. LCP-cased probes for EV batteries withstand 1,000 cycles without cracking, unlike polyamide alternatives which fail after 200 cycles.

Read recommendations:

Leading Pogo Pin connector manufacturer