Time:2025-12-04 Views:1 source:News

Touch screen test probes are specialized tools designed to verify the functionality, accuracy, and reliability of touch screen interfaces across various devices, including smartphones, tablets, industrial control panels, and automotive infotainment systems. Their primary role is to simulate user touch inputs and measure the screen’s response, ensuring that every touch point is detected correctly, without lag or misregistration. These probes are engineered to mimic the electrical and physical properties of human fingers, as most touch screens—whether capacitive or resistive—respond to specific stimuli such as capacitance or pressure.

One of the key technical features of touch screen test probes is their adjustable contact force and tip design. The tip, often made of conductive materials like conductive rubber or metal alloys, must be soft enough to avoid scratching the screen surface yet rigid enough to maintain consistent contact during testing. Many advanced models also come with precise positioning systems, allowing them to test specific coordinates on the screen with micron-level accuracy, which is crucial for detecting dead zones or areas with weak sensitivity. Additionally, these probes are integrated with testing equipment that records response times, signal strength, and error rates, providing quantitative data for quality control.

In manufacturing environments, touch screen test probes are indispensable for batch testing. They streamline the quality assurance process by automating repetitive touch tests, reducing human error and increasing efficiency. For example, in a smartphone production line, a probe can quickly perform a sequence of taps, swipes, and pinches across the entire screen to ensure uniform performance. They also play a vital role in research and development, helping engineers optimize touch screen designs by identifying areas where sensitivity can be improved or response times reduced. With the growing demand for high-performance touch screens in various industries, the precision and versatility of these test probes continue to evolve to meet new technical challenges.

Read recommendations:

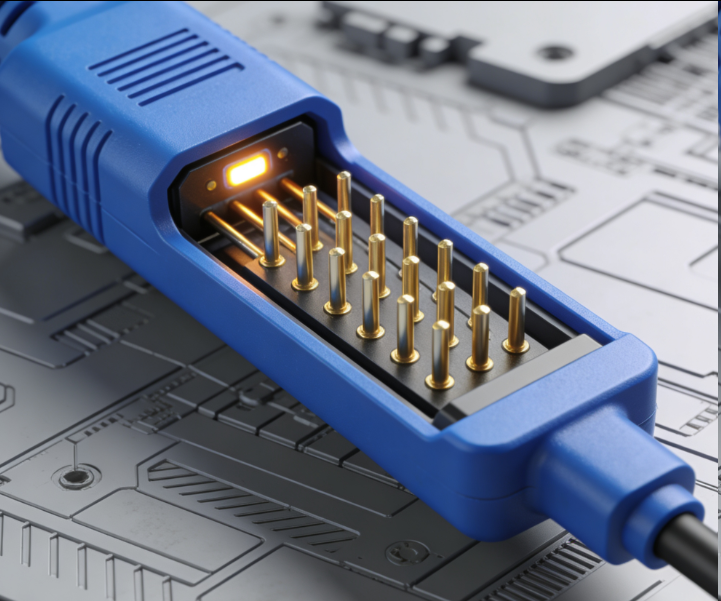

Direct supply from Magnetic PogoPin factory

Energy storage connector metal terminal