Time:2025-12-19 Views:1 source:News

TV test probes are specialized diagnostic tools designed to measure, detect, and analyze electrical signals, voltage, and component performance in television sets—including LCD, OLED, QLED, and traditional CRT TVs. Unlike general-purpose electrical probes, they are optimized for the unique signal characteristics of TV systems (e.g., high-frequency video signals, low-voltage control signals, and complex power supply circuits) and are used by repair technicians, quality control engineers, and TV manufacturing professionals to troubleshoot faults, verify performance, and ensure compliance with industry standards. The core function of TV test probes is to provide accurate, non-destructive access to internal TV circuits, enabling users to identify issues like faulty backlights, signal distortion, power supply failures, or defective driver boards without damaging sensitive components.

Key features of TV test probes tailored to TV diagnostics include:

Signal compatibility for TV-specific waveforms: TVs generate and process a range of specialized signals—video signals (e.g., HDMI, LVDS, T-CON signals), audio signals (analog and digital), and power supply signals (e.g., 12V, 24V for backlights, 5V for control circuits). TV test probes are calibrated to handle these signals: high-frequency probes (with bandwidths of 100MHz-500MHz) capture fast-changing video signals without distortion, while low-voltage probes (sensitive to 0.1V-1V) accurately measure weak control signals from the TV’s mainboard. For example, an LVDS probe (used for LCD TV T-CON boards) has a differential design to reduce noise interference, ensuring clear measurement of the high-speed data streams that drive the display panel.

Non-invasive and safe contact designs: TV internal circuits are densely packed with small, sensitive components (e.g., SMD resistors, capacitors, and integrated circuits). To avoid damaging these parts, TV test probes feature fine, insulated tips (often 0.5mm-1mm in diameter) made of conductive materials like copper or gold-plated steel—allowing precise contact with tiny solder points or component leads. Some probes also include spring-loaded tips to apply gentle pressure, preventing slippage and reducing the risk of short-circuiting adjacent pins. For high-voltage circuits (e.g., TV power supplies), insulated probes with voltage ratings of 1000V+ ensure user safety during measurements.

Integration with diagnostic tools: Most TV test probes are designed to work with complementary equipment like oscilloscopes (for waveform analysis), multimeters (for voltage/current measurement), or signal generators (for injecting test signals). For example, a probe paired with an oscilloscope can display the waveform of a TV’s backlight inverter signal—helping technicians identify if the inverter is producing a stable output (a distorted waveform indicates a faulty inverter). Some advanced probes include built-in LED indicators to show signal presence (e.g., a red light for no signal, green for normal signal), providing quick visual feedback during initial troubleshooting.

Application-specific designs: Probes are tailored to different TV subsystems: backlight test probes (with long, thin tips to reach backlight LED strips inside the TV panel), T-CON board probes (with differential inputs to handle LVDS signals), and audio circuit probes (with shielded cables to reduce audio noise interference). For OLED TVs, specialized probes measure the low-voltage signals that control individual pixel brightness, helping diagnose issues like pixel burn-in or uneven brightness.

Practical uses of TV test probes:

Repair and troubleshooting: Technicians use probes to trace signals through the TV’s circuit boards—for example, measuring the voltage at the mainboard’s HDMI input to check if the TV is receiving a signal (no voltage indicates a faulty HDMI port or cable). They also test backlight LEDs by probing the LED strip connections (a drop in voltage across an LED indicates a dead bulb).

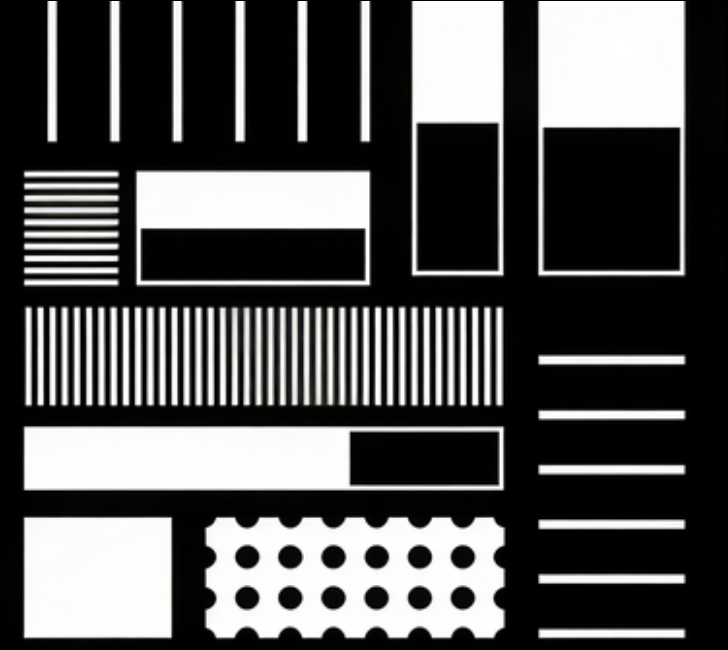

Quality control in manufacturing: During TV production, probes verify that each component meets specifications—e.g., checking that the power supply outputs the correct voltage (24V ±5%) or that the T-CON board transmits stable LVDS signals. This ensures only functional TVs reach the market.

Performance calibration: For high-end TVs (e.g., QLED models), probes measure color accuracy and brightness uniformity—helping technicians adjust settings like gamma or white balance to meet industry standards (e.g., Rec. 709 for HDTVs).

When selecting a TV test probe, consider factors like signal bandwidth (match it to the TV’s highest signal frequency), voltage rating (sufficient for the TV’s power circuits), and tip size (compatible with the TV’s component size). With their precision and specialization, TV test probes are indispensable tools for maintaining and repairing modern television sets.

Read recommendations:

European standard charging cable

European standard socket five-piece set