Time:2025-12-10 Views:1 source:News

Pogopin probe installation requires precision alignment, controlled insertion force, and compatibility with application scenarios, with two primary approaches: manual installation for small-scale production and automated installation for mass manufacturing. Both methods prioritize stable mechanical fixation and reliable electrical contact to ensure long-term performance.

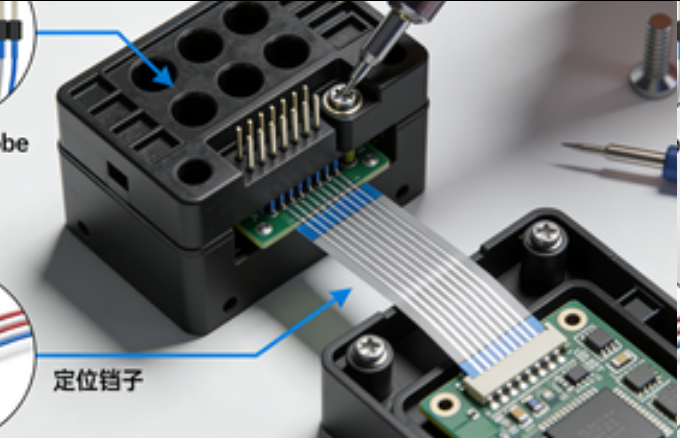

Manual installation is ideal for low-volume production or prototype assembly, relying on basic tools and careful operation. First, prepare a hand press, pin-driving chuck (matched to the probe diameter), and the target PCB or housing with pre-drilled mounting holes (tolerance ±0.02mm to ensure alignment) . Insert the pogopin into the chuck—for micro-probes under 1mm diameter, secure it manually to avoid deformation. Align the exposed probe head with the mounting hole, then apply uniform pressure via the hand press handle until the probe reaches the preset insertion depth (typically flush with the PCB surface or protruding 0.5–1mm as required). Post-installation, verify fixation by gently wiggling the probe; no lateral movement indicates successful mounting. This method offers low upfront costs and flexible adjustment, suiting small workshops or R&D teams .

Automated installation is designed for high-volume manufacturing, leveraging specialized machinery to ensure consistency and efficiency. The process begins with loading pogopins into a vibratory feeder, which orients them uniformly and feeds them to the shuttle mechanism . The shuttle positions each probe under the insertion quill, which descends with calibrated force (usually 5–20N, depending on probe size) to press the probe into the mounting hole. Advanced machines integrate vision systems to inspect alignment in real time, rejecting misaligned components to maintain yield. Automated installation reduces human error, achieves cycle times under 1 second per probe, and is essential for consumer electronics production lines (e.g., smartwatch charging contacts or smartphone test fixtures) .

Regardless of the method, post-installation checks are critical. Verify insertion depth consistency (variation ≤0.03mm) and conduct a pull-out test (minimum 5N force for PCB-mounted probes). For SMT-type pogopins, ensure the flat base is fully contacting the solder pad before reflow soldering (temperature compatible with the probe’s plating material, typically 260°C for 10 seconds) . Proper installation prevents common issues like contact instability or probe detachment during use.

Read recommendations:

CCS1 to Tesla charging gun adapter terminal

High speed signal transmission pogopin for space - constrained devices