Time:2025-09-17 Views:1 source:News

Pogopin pressure sensing probes represent a specialized type of electrical connector that combines the functionality of a traditional pogopin with pressure - sensing capabilities. These probes are designed to not only establish electrical connections but also measure the pressure applied during the connection process, making them highly valuable in a wide range of applications.

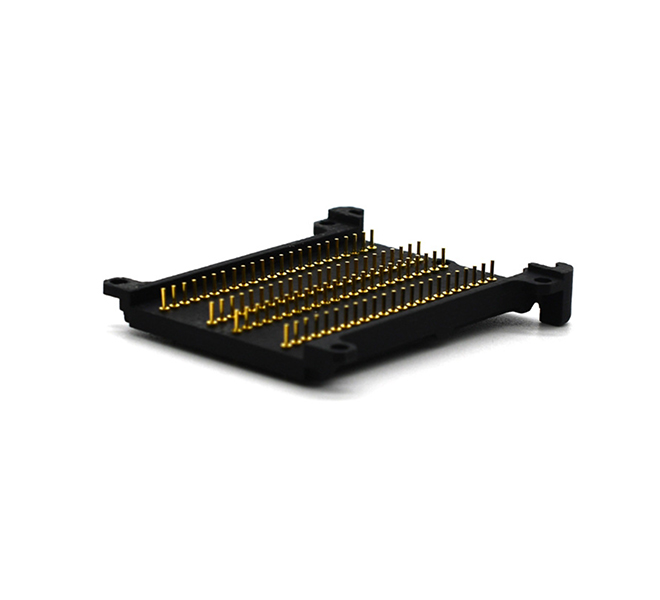

At the core of pogopin pressure sensing probes is their unique structure. Similar to standard pogopins, they consist of a spring - loaded plunger, a barrel, and a tip. However, what sets them apart is the integration of a pressure - sensing element, typically a strain gauge or a capacitive sensor. The strain gauge, for example, works by deforming under pressure, which changes its electrical resistance. This change in resistance can be measured and correlated to the amount of pressure applied to the probe tip. Capacitive sensors, on the other hand, detect pressure - induced changes in capacitance.

The performance advantages of pogopin pressure sensing probes are significant. They offer high - precision pressure measurement, often with an accuracy of within a few percentage points. This precision is crucial in applications where accurate pressure monitoring is essential, such as in semiconductor manufacturing. In the production of microchips, these probes can be used to measure the pressure during the bonding process of components, ensuring that the correct amount of force is applied to avoid damage to delicate circuitry while achieving a reliable connection.

These probes also have excellent repeatability, meaning they can consistently provide accurate pressure readings over multiple cycles. This makes them suitable for automated manufacturing processes where the same connection and pressure - measurement tasks are repeated thousands of times. Additionally, pogopin pressure sensing probes are highly durable, with the spring - loaded design allowing them to withstand repeated insertion and extraction cycles without significant wear or loss of performance.

In terms of applications, pogopin pressure sensing probes are widely used in the electronics industry. They are employed in the assembly of printed circuit boards (PCBs) to measure the pressure when components are being soldered or inserted. In the automotive industry, they can be used to monitor the pressure in fuel injection systems or in the connection of various electrical components, ensuring reliable operation and safety. They also find applications in the medical field, for example, in devices that require precise pressure sensing during procedures or in the monitoring of physiological parameters.

Read recommendations:

communication equipment Magnetic PogoPin