Time:2025-11-12 Views:1 source:News

Pogo Pin engineering test probes are specialized electrical contact tools designed for the research, development, and prototyping phases of electronic product engineering. Unlike manufacturing probes optimized for high-volume cycles, these probes prioritize flexibility, precision, and compatibility with diverse test scenarios—catering to engineers testing new PCB designs, validating component performance, or troubleshooting prototype functionality. Their core applications include bench-top testing of circuit prototypes, environmental stress testing (e.g., temperature or vibration), and signal integrity analysis for high-speed electronic systems.

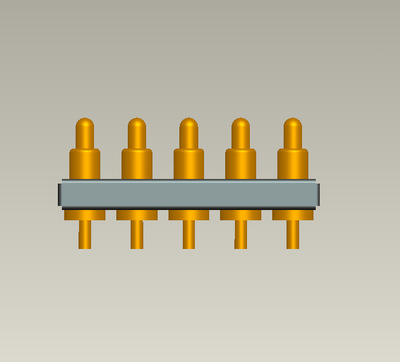

The technical design of engineering test probes emphasizes adaptability and measurement accuracy. They feature a highly customizable structure: interchangeable tips (e.g., conical, flat, or hook-shaped) to accommodate different component types (e.g., SMDs, through-hole components, or connector pins), adjustable spring forces (10 to 100 grams) to suit delicate prototypes or rugged industrial components, and a range of body sizes (from 0.5mm to 5mm diameter) for access to tight spaces in prototype enclosures. The probe materials are selected for both conductivity and durability—beryllium copper pins with gold plating (2–50 microinches) ensure low contact resistance (less than 30 milliohms) and resistance to oxidation, critical for consistent measurements over extended testing periods.

In engineering workflows, these probes support a wide range of test methodologies. For signal integrity testing (e.g., in 5G or Ethernet devices), high-frequency Pogo Pin probes (with bandwidths up to 40 GHz) enable accurate measurement of signal rise times, jitter, and crosstalk—helping engineers optimize PCB trace layouts or component placement. During environmental testing, ruggedized models (with IP65 ratings or temperature resistance from -55°C to 150°C) maintain reliable contact even in extreme conditions, such as testing automotive electronics in high-temperature chambers or aerospace components in vibration simulators. They also integrate with specialized test equipment, such as oscilloscopes, multimeters, or network analyzers, via standard connectors (e.g., SMA, BNC, or banana plugs), ensuring seamless data capture and analysis.

Practical benefits for engineers include accelerated prototyping cycles and improved design validation. The interchangeable tips and adjustable spring forces eliminate the need for multiple probe sets, reducing setup time when switching between test tasks (e.g., from measuring a resistor’s value to testing a connector’s signal transmission). The high measurement accuracy helps engineers identify design flaws early—e.g., a weak solder joint or a signal reflection issue—before moving to mass production, saving time and costs. Additionally, many engineering test probes are compatible with 3D-printed custom fixtures, allowing engineers to quickly create test setups for unique prototype designs. For electronic engineers, these probes are essential tools that turn complex testing requirements into manageable, precise tasks, enabling innovation and reliable product development.

Read recommendations:

Mass production of magnetic connector factory

Pogo Pin Connector for Automation Equipment

Side - Mounted Pogo Pins for Mobile Phones

Efficient production of Magnetic PogoPin for Smart Wearable Devices