Time:2025-12-03 Views:1 source:News

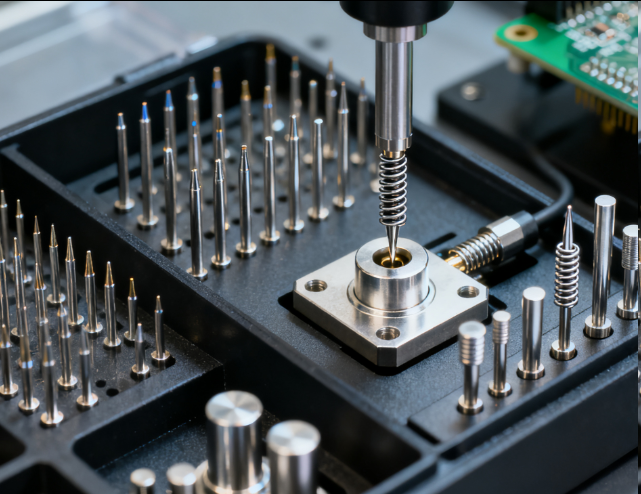

Interchangeability ensures compatibility across devices and manufacturers, critical for modular systems like smartphones and industrial controllers.

Standardization Efforts:

Pitch and Size Norms: The EIAJ RC-5320 standard defines 0.4mm, 0.5mm, and 1.0mm pitches for consumer electronics. For example, Apple’s MagSafe chargers use 0.5mm-pitch PogoPins, enabling third-party accessory compatibility.

Mechanical Tolerances: ISO 3274 specifies ±0.02mm dimensional accuracy for needle heads. Probes with C-type clamps (for 1.27mm DIP packages) achieve 99.9% insertion success rates in automated assembly lines.

Design for Compatibility:

Dual-Contact Points: Used in laptop batteries to mitigate vibration-induced disconnections. This design reduces contact loss from 15% (single-point) to <0.1% in automotive IGBT testing.

Magnetic Alignment: Combines PogoPins with magnets in wireless chargers, ensuring self-centering within ±0.1mm. Samsung’s 15W MagSafe-compatible chargers achieve 98% alignment accuracy.

Challenges and Solutions:

Material Mismatch: Mixing gold-plated and silver-plated probes in the same circuit risks galvanic corrosion. Solutions include unified PdNi plating or dielectric coatings.

Thermal Expansion: Probes in EV charging modules face mismatched expansion rates (BeCu: 17ppm/°C, stainless steel: 16ppm/°C). Compliant spring designs absorb 0.1mm thermal drift without contact loss.

Industry Adoption:

Automotive Tier-1 Suppliers: Adopt standardized probes for BMS testing, reducing validation costs by 30%.

Consumer Electronics OEMs: Use modular PogoPin arrays in smartphones, cutting R&D cycles by 20% through plug-and-play compatibility.

By adhering to material science principles, rigorous testing protocols, and interchangeability standards, PogoPin probes achieve reliability across diverse applications, from microelectronics to high-power industrial systems.

Read recommendations: