Time:2026-01-09 Views:1 source:News

Fatigue resistance testing of Pogopin Probes is a critical process that evaluates the ability of these components to withstand repeated mechanical and electrical stresses over an extended period. Pogopin probes are subjected to cyclic loading during their operation, including the repeated compression and extension of the plunger, as well as the continuous flow of electrical current. Over time, these cyclic stresses can lead to fatigue failure, which may result in intermittent electrical connections, increased contact resistance, or even complete failure of the probe. Conducting comprehensive fatigue resistance testing is essential to ensure the reliability and long - term performance of Pogopin Probes in various applications.

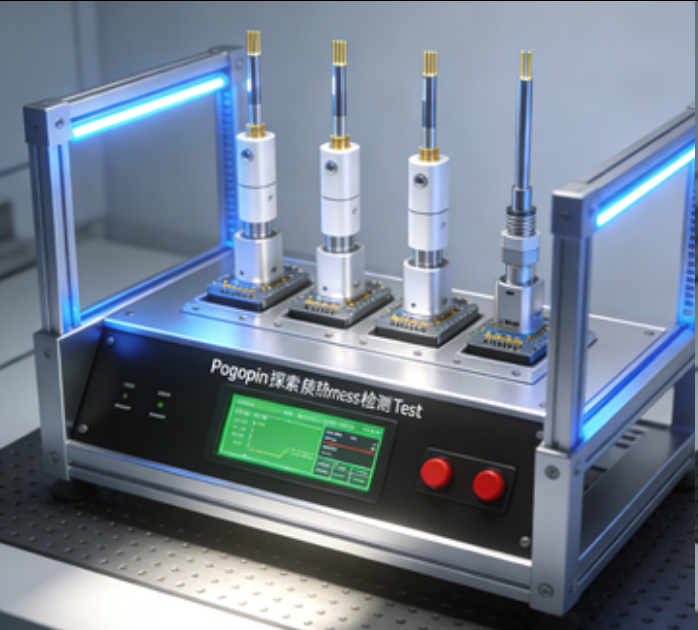

The fatigue resistance testing of Pogopin Probes typically involves simulating real - world operating conditions in a controlled laboratory environment. One common method is to subject the probes to a specified number of mating and de - mating cycles. During each cycle, the plunger of the pogopin probe is compressed and released, mimicking the connection and disconnection processes that occur during actual use. The number of cycles can range from thousands to millions, depending on the application requirements and industry standards. Throughout the testing process, various parameters are monitored, such as contact resistance, mechanical displacement of the plunger, and any signs of physical damage or wear on the probe components.

In addition to mechanical cycling, electrical fatigue testing is also crucial. Pogopin probes are often required to carry electrical current, and the repeated flow of current can cause thermal and electrical stresses within the probe. Electrical fatigue tests involve applying a specific electrical load, including voltage and current, to the pogopin probe for an extended period while monitoring the electrical performance. This helps to identify any potential issues related to electrical degradation, such as the formation of oxidation layers on the contact surfaces or the fatigue of the internal electrical conductors.

Advanced testing techniques, such as non - destructive testing methods, are also employed during fatigue resistance testing. Techniques like ultrasonic testing or microscopic inspection can be used to detect any internal defects or early signs of fatigue damage that may not be visible to the naked eye. By analyzing the results of these tests, manufacturers can optimize the design and material selection of Pogopin Probes to improve their fatigue resistance. For example, if a particular material shows signs of premature fatigue, an alternative material with better fatigue properties can be considered. Fatigue resistance testing is an essential part of the quality control process for pogopin probes, ensuring that they can withstand the rigors of real - world use and provide reliable electrical connections over their intended lifespan.

Read recommendations:

Low - Resistance Smart Wearables Magnetic Connector for Efficient Power Transfer