Time:2026-01-08 Views:1 source:News

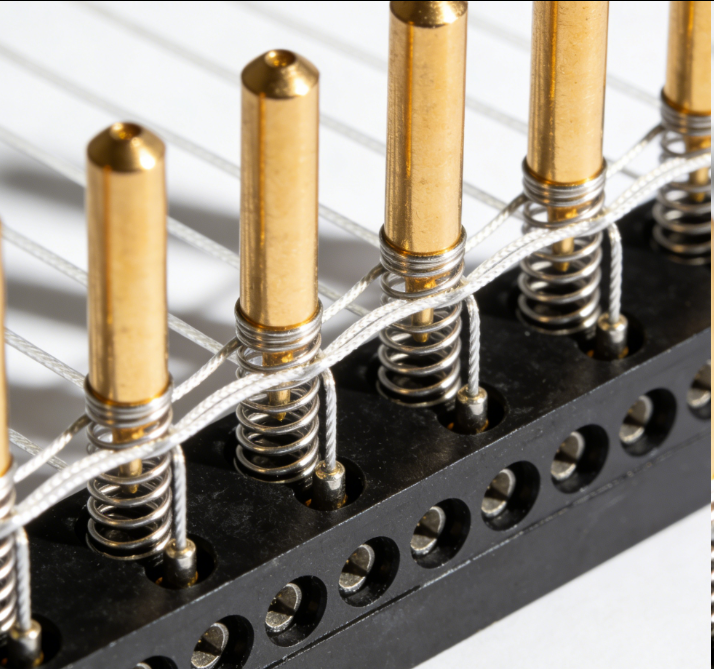

The choice of electrode materials for pogopin probes is a critical factor that significantly influences their electrical performance, durability, and overall reliability. Pogopin probes are used in a wide variety of applications, from consumer electronics to industrial equipment, and the right electrode materials are essential to meet the diverse requirements of these applications. Different materials possess unique properties such as electrical conductivity, corrosion resistance, hardness, and cost - effectiveness, which need to be carefully considered during the material selection process.

One of the most commonly used electrode materials for pogopin probes is copper. Copper is highly valued for its excellent electrical conductivity, which ensures low electrical resistance and efficient transmission of electrical signals or power. It also has good formability, allowing for easy manufacturing of the probe components. However, copper is prone to oxidation and corrosion over time, especially when exposed to moisture and air. To address this issue, copper - based pogopin probes are often plated with other materials, such as nickel, gold, or silver. Nickel plating provides a protective layer that enhances the corrosion resistance of the copper, while gold and silver plating not only improve corrosion resistance but also offer superior electrical conductivity and reduced contact resistance, making them suitable for high - performance applications.

Gold is another popular electrode material for pogopin probes, particularly in applications where high reliability and long - term stability are required. Gold has excellent corrosion resistance, does not oxidize easily, and can maintain a stable electrical contact even in harsh environments. It also has a low contact resistance, which is beneficial for applications involving high - frequency signals or low - voltage power transmission. However, gold is relatively expensive, so it is often used in combination with other base materials, such as copper or nickel, in the form of plating to balance cost and performance.

Stainless steel is also used as an electrode material for pogopin probes in some applications. Stainless steel offers good mechanical strength, corrosion resistance, and wear resistance. It is suitable for applications where the probes are subjected to mechanical stress, vibrations, or harsh environmental conditions. While stainless steel has lower electrical conductivity compared to copper or gold, its overall performance in terms of durability and mechanical stability makes it a viable option in certain industrial and automotive applications. The selection of electrode materials for pogopin probes requires a comprehensive evaluation of the application requirements, material properties, and cost - benefit considerations to ensure optimal performance and reliability of the probes.

Read recommendations:

Ruggedized Reliable contact force magnetic connector for Harsh Environments