Time:2025-10-18 Views:1 source:News

The contact area of pogopin probes is a crucial parameter that affects the electrical conductivity, mechanical stability, and overall performance of the connection. A larger contact area generally results in lower contact resistance, better heat dissipation, and more reliable electrical connections, while a smaller contact area might be preferred in applications where space is limited or precise positioning is required.

Several factors influence the contact area of pogopin probes. The design of the probe tip is a primary determinant. Probe tips come in various shapes, such as round, flat, pointed, or conical. A flat - tipped pogopin probe typically provides a larger contact area compared to a pointed one, as it distributes the contact pressure over a broader surface. The diameter of the probe tip also directly impacts the contact area; a larger - diameter tip will have a greater surface area in contact with the mating component. Additionally, the surface finish of the probe tip and the mating surface plays a role. A smooth and polished surface can increase the effective contact area by reducing the microscopic irregularities that might prevent full surface - to - surface contact.

Calculating and optimizing the contact area is important in different applications. In high - current electrical connections, a larger contact area is desirable to minimize the contact resistance and prevent overheating. For example, in electric vehicle battery packs, pogopin probes with larger contact areas are used to ensure efficient power transfer and reduce the risk of electrical failures due to excessive resistance. In contrast, in micro - electronic devices, where components are densely packed, pogopin probes with smaller contact areas are often utilized to fit within the limited space while still maintaining reliable electrical connections.

Testing the contact area of pogopin probes can be done through various methods. Scanning electron microscopy (SEM) can be used to visualize and measure the contact area at a microscopic level, providing detailed information about the surface morphology and contact points. Electrical resistance measurements can also indirectly indicate the effectiveness of the contact area. A lower contact resistance generally suggests a larger and more efficient contact area. By carefully considering and optimizing the contact area of pogopin probes, engineers can design electrical connection systems that meet the specific requirements of different applications, ensuring reliable performance and efficient operation.

Read recommendations:

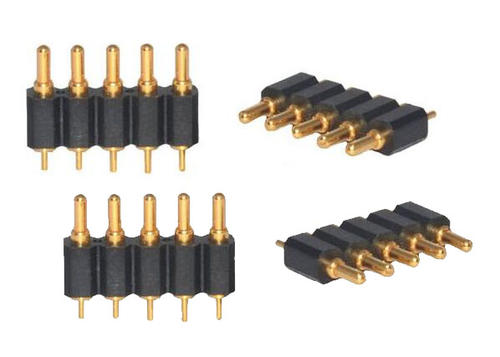

Convenient installation of Pogo Pin Connector